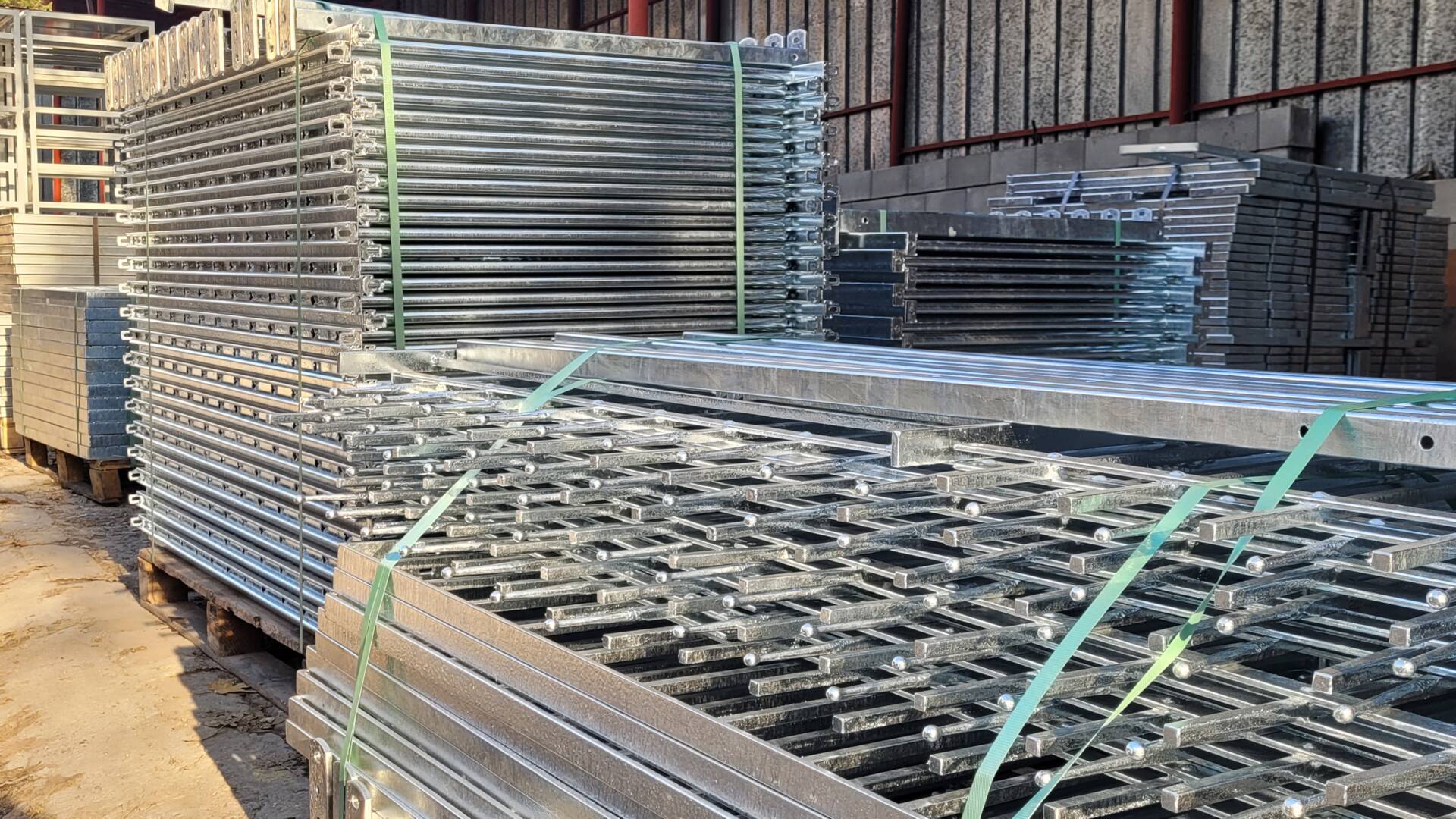

Zinc coating protects steel structures for decades and minimizes the need for maintenance. It is the most environmentally friendly corrosion protection process available..

Almost all of our products go through a hot-dip galvanizing process, and every week we organize transport in both directions. Upon request, you can bring your material, which you want galvanized, we will transport it to Balkanzinc AD company. Ruse and within a period of up to 10 days we will bring it back for you to get it from us.

Please pay special attention to the requirements, which your material must meet, to obtain a quality zinc coating:

REQUIREMENTS

VENTILATION AND DRAINAGE OPENINGS

– providing access to any internal surface and then draining the molten zinc, such as not using openings below f8mm.

METAL SURFACE

– the metal should not be excessively corroded

– in the presence of welds, the slag must be cleaned

– the surface must be cleaned of oil, mild paint or grease

A clean steel surface is a basic requirement for quality hot-dip galvanizing.

Contamination in the form of grease, tar, paint and welding slag cannot be removed by chemical cleaning and can be the cause of black, exposed spots after galvanizing.

Sometimes surface contamination is difficult to detect and only becomes apparent after galvanizing.

CHEMICAL COMPOSITION OF METAL

In order to achieve optimal quality of hot-dip galvanizing, the following chemical elements must be within the specified limits:

- silicon less than 0,04% or between 0,15% and 0,24%

- phosphorus less than 0,04%.

- carbon content under 0,25%

- manganese less than 1,3%

If you need more information about hot dip galvanizing you can visit our partner site – company Balkanzinc AD, city of Ruse or call us!